26.02.2024

Unternehmenszukauf von Sweden Entry Tools (SET) Breaching komplettiert Portfolio an taktischen Zugangslösungen

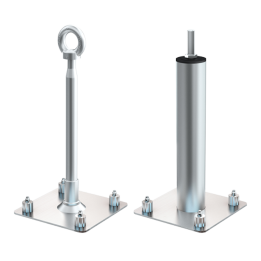

SKYLOTEC erweitert sein Portfolio im Bereich der taktischen Zugangslösungen durch die Übernahme von Sweden Entry Tools AB (bekannt unter dem Namen SET Breaching), dem weltweit führenden Anbieter von mechanischen Breaching-Lösungen und Trainingsausrüstung. Die Übernahme erfolgt durch SKYLOTEC Nordic AB, die schwedische Niederlassung von SKYLOTEC.

Weiterlesen → weiterlesen